The Device Chronicle interviews Clarisa Doval, Head of Digital Solutions, Continental, on building new business models based on IoT connectivity and firmware updates.

A special thanks to Christine Schawe, Marketing Communications Manager, Digital Solutions, Continental, for facilitating this executive interview.

Clarisa Doval leads the digital solutions strategy at Tier 1 automotive leader Continental. Continental develops pioneering technologies and services for sustainable and connected mobility of people and their goods. Founded in 1871, the technology company aims to offer safe, efficient, intelligent and affordable solutions for vehicles, machines, traffic and transportation. In 2022, Continental generated sales of €39.4 billion and currently employs around 200,000 people in 57 countries and markets.

Clarisa Doval leads the digital solutions strategy at Tier 1 automotive leader Continental. Continental develops pioneering technologies and services for sustainable and connected mobility of people and their goods. Founded in 1871, the technology company aims to offer safe, efficient, intelligent and affordable solutions for vehicles, machines, traffic and transportation. In 2022, Continental generated sales of €39.4 billion and currently employs around 200,000 people in 57 countries and markets.

The Tires group sector has 24 production and development locations worldwide and is one of the leading tire manufacturers with 57,000 employees and posted sales of €14 billion in 2022 in this group sector. Continental ranks among the technology leaders in tire production and offers a broad product range for passenger cars, commercial and special-purpose vehicles as well as two-wheelers. Through continuous investment in research and development, Continental aims to make a major contribution to safe, cost effective and ecologically efficient mobility. The portfolio of the tire business includes services for the tire trade and fleet applications, as well as digital management systems for tires.

Connected services expert

Clarisa has a strong track record and considerable expertise in developing connected services while in a previous leadership position at Airbus, where she led Digital Cabin and Connected Products and Services for Commercial Aircraft. At Continental, Clarisa leads the Digital Solutions organization, focusing on developing IoT solutions for all types of vehicles.

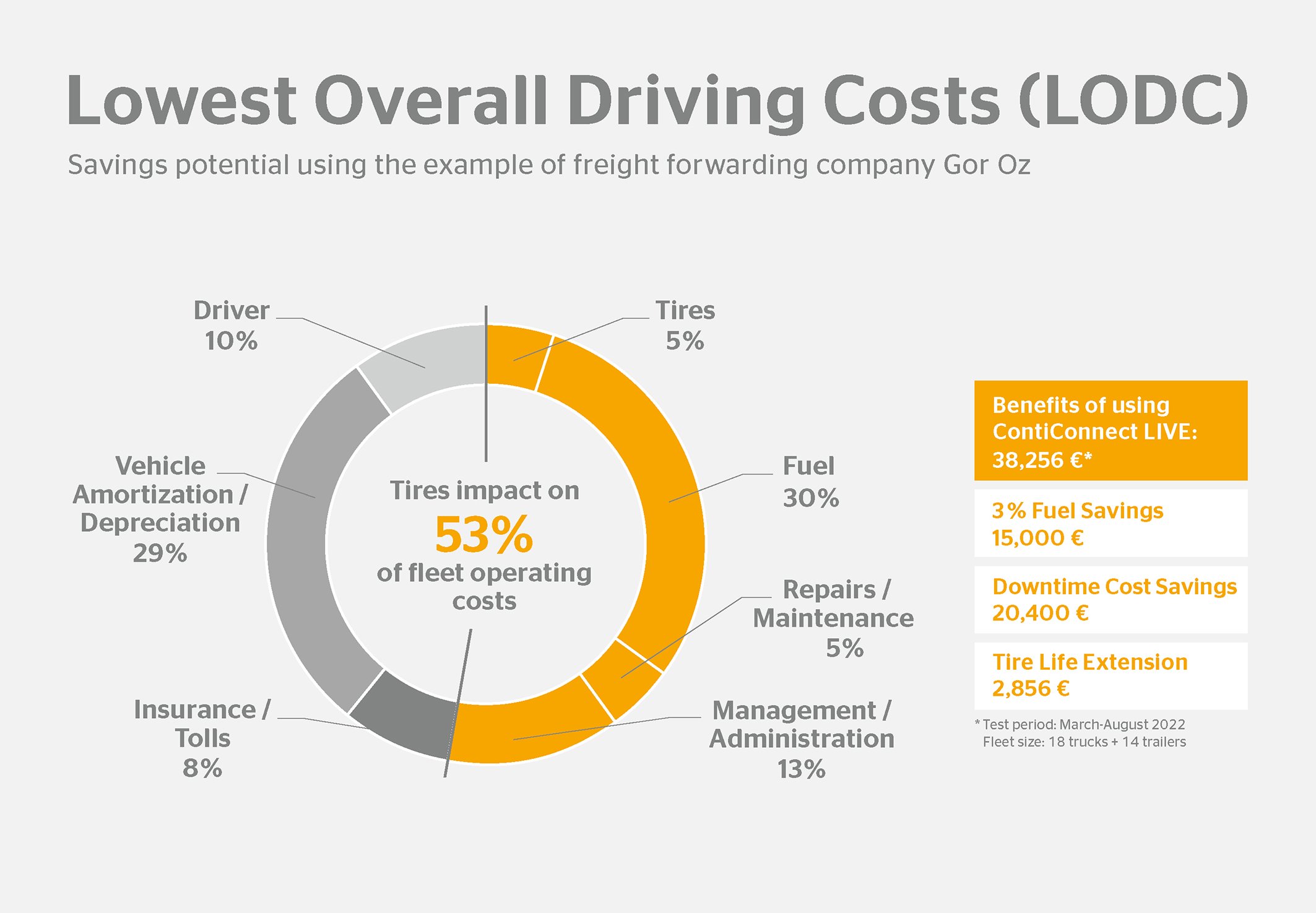

Lowest overall driving cost

Clarisa's team developed the first solution for optimizing the cost of tires for the entire fleet of their customers. Clarisa champions the concept of the lowest overall driving cost (LODC). She explains that typically for customers, 5% of their fleet operation cost comes from buying and managing the tires over their lifetime but they have an impact of 53 percent of the operating costs. Clarisa and her group are working on ways to use digital connectivity and data analytics to detect signals of potential tire failure and extend the lifetime of the tires through managed intervention and remediation.

Continental can take over the complete tire management and leverage telematics and sensors to do proactive monitoring of the tire health of the fleet. Clarisa explains, "Sensors are put in the tires to capture data, combining it with data from other components/systems in the vehicle, and then sent to a cloud platform called ContiConnect where algorithms generate alerts and decision support for predictive maintenance of the tires within a fleet."

Proven ROI

![]()

Clarisa cites one enterprise customer with fleets of trucks that deliver nondurable goods. Underinflated tires break more often, so they use yard readers in the depots and sensors in tires to read the tire pressure. Breakdowns went down to almost 0% due to optimal tire pressure. The customer realized a saving of between €500k and €600k per year from this use case alone.

The following saving and cost reductions are possible based on sample data UK customer, fleet size 55+, and within 12 months of using the ContiConnect solution:

- Reduce breakdowns by 83%, avoiding costly downtime:

- Achieve an average monthly fuel saving of €1910 and higher overall revenue

- Reduce after-hours calls by 95%

This use case explains the full ROI.

The Continental sales force uses a benefits calculator to show customers the projected ROI from investment in the service.

Collaborative effort

Clarisa describes the go to market in Digital Solutions as a highly collaborative effort. Clarisa and her immediate digital solutions team ideate the solution and handle everything from production to customer care. Still, there are dependencies on other units all along the way, including engineering, operations, cybersecurity, compliance, and customer service.

Clarisa also explained that the Digital Products unit looks at the problem in R&D and builds simple solutions combining hardware, software, and physical services. "Tyres have to be mounted, so they have to have a physical service component built in."

Tire-as-a-service

Tire-as-a-service comes in two flavors of service ContiConnect Live or ContiConnect Yard. "Certain customers will buy the hardware upfront with a lower subscription fee; other customers don't want to buy the hardware upfront but would rather pay a higher services subscription fee. We are just at the beginning of the new business model definition in this connected industry."

Continental provides them with yard readers for their depots under the ContiConnect Yard product.

ContiConnect Live is for customers who want to know and be aware of the tire condition in real time via live monitoring. This makes sense for vehicles on the road. In this scenario, Continental installs electronic units inside the vehicle. In this solution, there is a CCU or telematic unit that connects to the sensors. It is not usually possible to conjoin this central control unit (CCU) to the existing micro control units (MCUs) and electronic control units (ECUs) already installed inside the vehicle; in any case, they cannot read the Continental sensors, which are RF-based, so there is always a need to install electronics that are bridging to the rest of the vehicle. The CCU or telematics box within the vehicle sends the data to the cloud. Continental has a new product line with a CCU combined with the telematics box in one unit, so hardware installation and scale are much more manageable.

![]()

![]()

Security by design

Clarisa manages the security by design aspects of the product management but depends on the cybersecurity unit and a compliance unit that deals with homologation and product certification too. The cybersecurity, standards and regulations, and the compliance teams are fundamental parts in the homologation and certification of our products. “They always have to "bless" any solution before it goes to market. External regulatory bodies must also certify the products before launching on to the market."

Importance of firmware updates for product upgrades

Secure over the air (OTA) software updates are essential in extending the life of products: Clarisa shares an example: the current Tire-as-a-service is now on a generation two sensor, but the Digital Solutions group will be launching a replacement generation three sensor in 2024. Firmware software updates will allow the existing hardware to be retained by the customer. The firmware will be flashed on the embedded system (CCU and sensor) to add the new capabilities.

We wish Clarisa and her colleagues well as they continue to build business models based on connectivity that reduce costs and increase value for customers.